Ga. Tech, Piedmont Scientists Develop 3-D-Printed Heart Valves

Tasnim Shamma / WABE

An audio version of this story

Heart valves are the tubes that carry blood through your heart. As we age, sometimes they get clogged and need to be replaced.

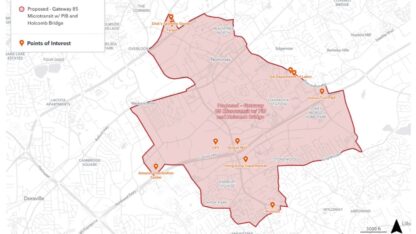

To help cardiologists pick the right size of prosthetic valves, researchers at Georgia Tech teamed up with scientists at the Piedmont Heart Institute to develop 3-D-printed heart valves.

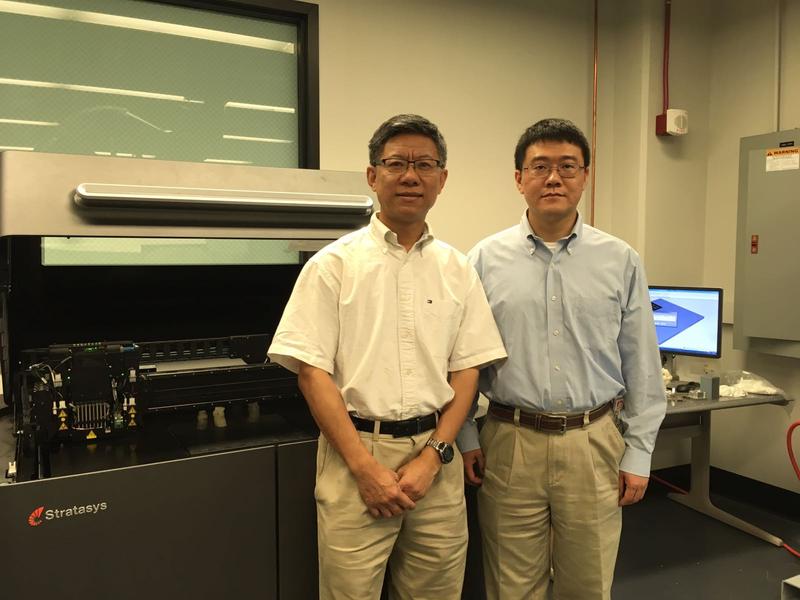

At Georgia Tech’s Manufacturing Institute, industrial and systems engineering professor Chuck Zhang showed off a large, black machine that looks almost like an oversized office scanner.

It’s a 3-D printer and sitting on top is a 4-inch tube model of a heart valve, printed layer by layer over the course of a few hours.

It looks like rubber but is made of a material similar to acrylic that is soft to the touch.

Heart Valve Replacement

Doctors and researchers at The Piedmont Heart Institute reached out to Zhang a few years ago because they wanted to find a way to improve the success rate of heart valve replacement surgeries.

Right now, doctors use MRIs and CAT scans to measure the size of valves.

But studies find a 26 to 67 percent chance that a prosthetic valve will eventually leak because it’s not a good fit.

“With our 3-D printing, we can really make the heart valve that just mimics the human heart and then you can do a lot of experiments,” Zhang said.

These experiments use human-like tissue instead of traditional testing on pigs.

Leakage

Before putting a prosthetic valve in a patient, doctors using this technology will now be able to test for leakage.

A study of 18 patients using retrospective data found a 90 percent accuracy rate comparing what happened with a simulation of blood using liquids flowing through the 3-D-printed heart valves and what happened in real-life with patients.

The 3-D-printed models look and feel like a real human heart valve and can be patient specific, so if patients have a lot of calcium deposits blocking blood flow, which look like small black stones, it can reproduce that too.

Zhen Qian, Piedmont Heart Institute’s chief of cardiovascular imaging research, said it’s too early to claim it will revolutionize the field of cardiology.

“It has potential, especially when you can do some quantitative study before the procedure,” Qian said. “It can also help valve companies to design a better valve.”

Zhang said several companies and hospitals have expressed interest in commercializing and testing the 3-D-printed heart valves.

Manufacturing Technology

3-D printing was invented in the early 1980s, but it’s only become popular in the last decade. Zhang said it’s popular partly because of its ability “to make very complex shapes in a very short period of time.”

While small companies have been using them for years, larger companies like GE are starting to use them to manufacture parts like fuel nozzles.

“In the past they have to manufacture different components and assemble them together. Now they can just use one design and one machine to make these parts within like 20 hours,” Zhang said.

The cost of the raw materials for the 3-D-printed heart valve is about $200. The cost of a prosthetic valve on the market right now is about $30,000.

The researchers published their study Monday in the Journal of American College of Cardiology: Cardiovascular Imaging.

9(MDAxODM0MDY4MDEyMTY4NDA3MzI3YjkzMw004))