Georgia Tech Uses Crab Shells, Tree Fibers To Develop New Kind Of Plastic Wrap

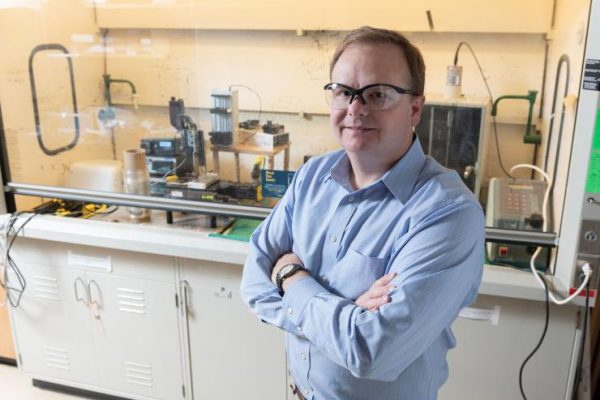

Georgia Tech professor Carson Meredith holds a new kind of film that could potentially replace plastic. It’s made of chitin found in the outer shells of seafood like crabs and cellulose nanocrystals found deep within tree fibers.

Tasnim Shamma / WABE

Dozens of cities like San Francisco and companies like Starbucks are looking for ways to reduce the amount of plastic going to landfills. Just one example is the recent surge in bans on plastic straws.

To meet some of this demand for renewable packaging, researchers at Georgia Tech have developed a new kind of packaging made of tree fibers and crab shells.

At Georgia Tech’s School of Chemical and Biomolecular Engineering building, professor Carson Meredith is holding something that looks like plastic.

The thin film is made by spraying two things together in water: cellulose nanocrystals, tiny particles extracted from deep within the cell walls of plants or trees, and something called chitin, found in the outer shells of seafood like crabs and shrimp.

“Our working theory was we could spray these together and have them aggregate to some extent because positive and negative are attracted, and that might lead to forming nice interfaces that would then be good barriers to oxygen, and that is a key characteristic of packaging, especially for food,” Meredith said. “These are compostable in industrial composting facilities, but they also are already consumed in the natural world, and they don’t accumulate in the environment. When shellfish die in the ocean, their shells are consumed, and same thing for trees in the forest.”

A new report from the Flexible Packaging Association found “green” plastic or bioplastics is just 1 percent of the global plastics market, but the amount of bioplastics manufactured is expected to increase 20 percent by 2022.

Cornell University chemistry professor Geoff Coates also makes biodegradable plastic, but out of carbon dioxide. He said one of the biggest obstacles to mass adoption is cost.

“If you go to the store and you forget your bag and you get to the checkout and they say we got this new fancy, you know, chitin-cellulose bag, but it’s going to cost you a dollar, people are going to be like, ‘What?’” Coates said.

Coates said there’s a big push in the food packaging industry for plastics that completely limit air from entering food.

“If you make a Coke bottle out of plastic, which they currently do, carbon dioxide can migrate through the film, and then your Coke goes flat,” Coates said. “And if you can make a plastic that doesn’t allow the migration either of carbon dioxide out or oxygen in, you can get a lot longer shelf life. You can make thinner bottles, and obviously then your food product stays fresher, not only in beverages but also meat.”

Georgia Tech has submitted patent applications for the invention, and professor Carson Meredith says it will take at least five years to finalize the design and development, as well as figuring out how to produce the raw materials in large volumes in a cost-effective manner.