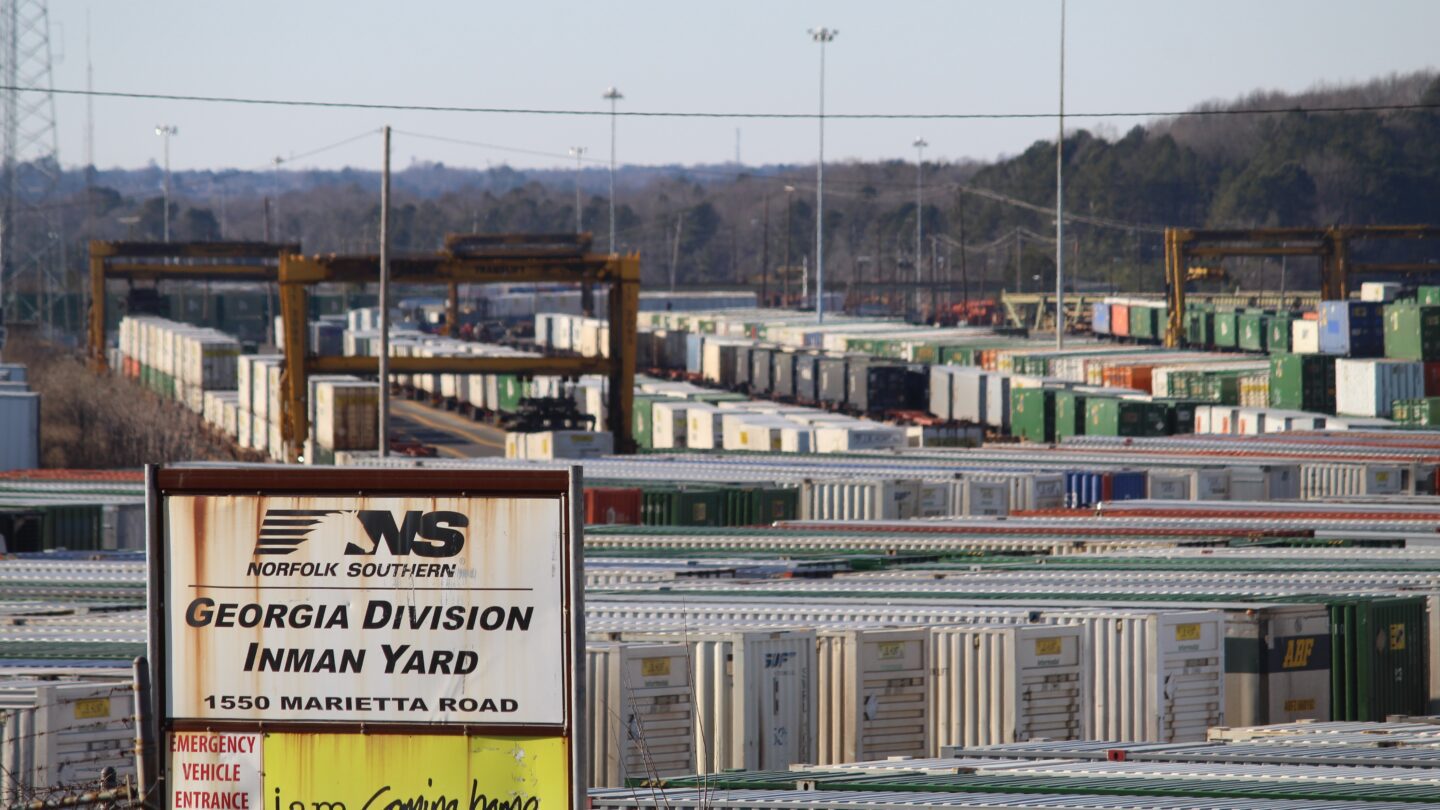

Norfolk Southern rolls out hybrid cranes in Atlanta to help handle thousands of shipping containers

Every day at Norfolk Southern’s Inman Yard intermodal facility in Northwest Atlanta, around a thousand shipping containers are delivered by train.

Awaiting their arrival is a fleet of giant overhead cranes with their square frames straddling the railroad tracks, ready to unload containers.

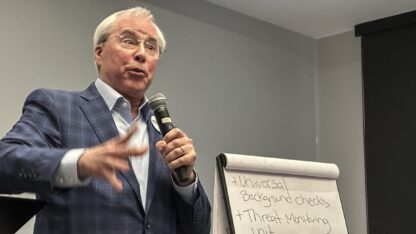

“Right now we’re hearing, actually, a crane in the background that’s diesel-powered,” said Josh Raglin, Norfolk-Southern’s chief sustainability officer as he stood inside the yard. “You hear how much noise that is?”

The Atlanta-based company has begun replacing the diesel-powered cranes used at its rail facilities with ones that operate mostly on electricity.

Workers are preparing three new 60-foot tall hybrid cranes, which are made by the manufacturer Konecranes. They’re expected to be in service soon. Raglin says not only will the new cranes be quieter and reduce greenhouse gas emissions – they’ll actually store up energy as shipping containers are lowered.

“When you’re going down, what the electric does is it captures that energy and it uses that energy to put back into the batteries,” said Raglin. “So most of the time they can run off just the electric power of capturing that lifting energy.”

Norfolk Southern says its Inman Yards facility processes 30,000 shipping containers a month, while the terminal in Austell handles some 50,000. A newly-announced facility in Gainesville will be able to handle 150,000 containers when it opens next year.

The company first introduced a handful of hybrid cranes in Chicago last year. It plans to upgrade its entire fleet of cranes to either hybrid or electric-only in the next decade.

“Electric units are much more reliable, so we’re going to have less maintenance, which means we’re going to have less down time,” said Raglin.

And better reliability could pay dividends for Norfolk Southern and others in the rail industry.

“Ports all around the country have been seeking to grow their volume base that flows on rail for many years,” said Tim Brown, who heads the Supply Chain and Logistics Institute at Georgia Tech.

He says a truck driver shortage made worse by the pandemic, and an emphasis on reducing traffic congestion and emissions, has brought rail to the forefront.

“Any container you can put on rail,” said Brown, “are containers that are taken off the congested roads.”